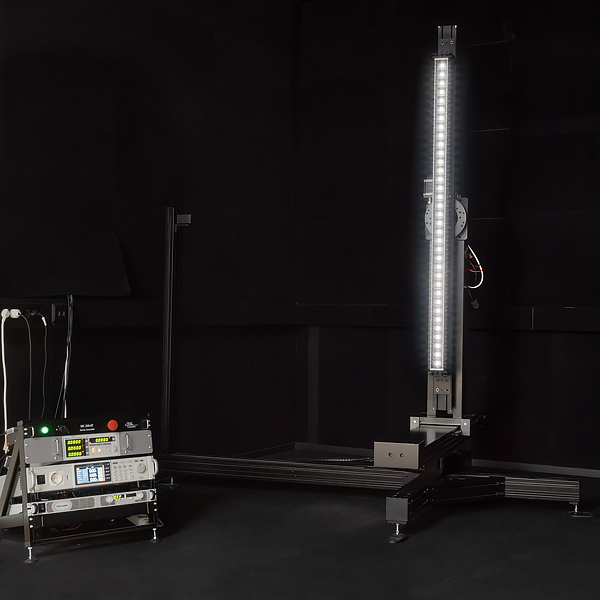

Goniophotometer

The goniophotometer is a key tool for measuring the optical properties of luminaires. It measures the light distribution of the luminaire, providing accurate data on luminous intensity and light direction. This information is essential in lighting design, as it helps optimize light distribution in a space and ensures the luminaire meets design criteria and standards. The light distribution data obtained from the measurement can be used to design optimized and energy-efficient lighting solutions.

The goniophotometer measures the light distribution of the luminaire at different angles, providing accurate data on luminous intensity and direction

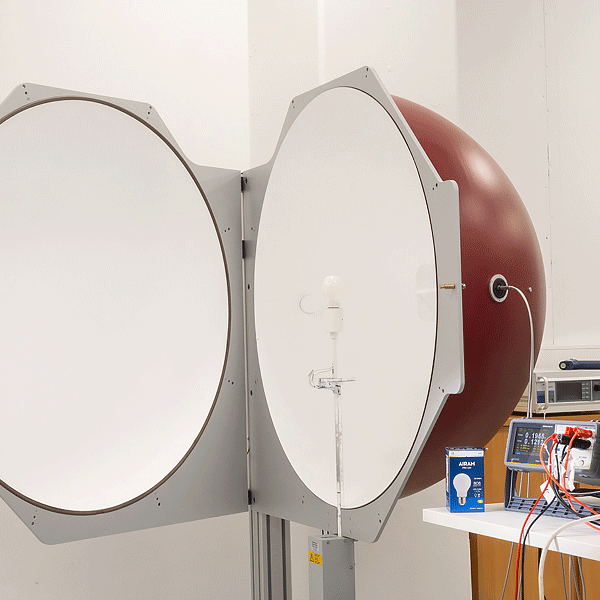

Integrating Sphere

The integrating sphere is a measurement device used to measure the total luminous intensity and spectral properties of light sources. The sphere has a highly reflective inner surface that evenly diffuses light, allowing for accurate and repeatable measurement results. This method can measure, among other things, luminous flux (lumens), color temperature (CCT), color indices (CRI, TM-30), light spectral distribution, and flicker. The data obtained with the integrating sphere is essential in the development and quality control of lighting products, ensuring that light sources meet required standards and performance requirements.

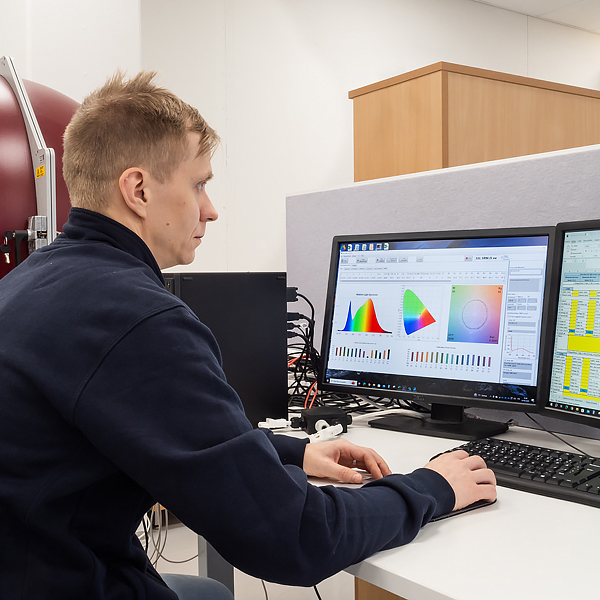

Dimming Testing in the Integrating Sphere

Dimming testing evaluates how the luminaire or lamp and dimmer work together at different dimming levels. The test can identify potential issues such as uneven dimming, possible color shifts in light, non-linear brightness adjustment, or noise produced by the dimmer.

The dimming test evaluates the compatibility of the light source and dimmer.

IPx4 Test

The IPx4 test chamber is a device used to test the water resistance of luminaires according to IP ratings. The test chamber simulates the effects of rain and splashing water on products to ensure their suitability for outdoor or damp indoor environments. Testing is performed according to standards EN 60529 and EN 60598-1. In the IPx4 test, the device being tested is exposed to water jets from all directions.

The IPx4 test ensures the water resistance of luminaires, making them suitable for damp or outdoor environments.

Comprehensive Measurements

Airam's test laboratory performs a wide range of measurements related to electrical safety and temperature management. Tests are conducted according to standards, ensuring the safety, functionality, and longevity of luminaires and lamps.

Temperature Measurements

Temperature measurements determine how the luminaire or lamp heats up during use. The test measures the temperatures of various components, such as the LED module, power supply, and housing. Temperature rise and distribution are important factors to evaluate, as excessively high temperatures shorten the lifespan of components and can affect light quality. Measurements also analyze how effectively the luminaire dissipates heat and maintains optimal operating parameters throughout its lifecycle. Temperature measurement results are used in product development, quality control, and ensuring compliance with standards. They help design energy-efficient and durable lighting solutions that operate reliably in various environments.

Electrical Safety Testing

Electrical safety testing ensures that luminaires and lamps meet safety requirements and prevent electrical shocks, short circuits, and other hazardous situations. Key testing methods include insulation resistance measurement and grounding continuity measurement.

Insulation Resistance Measurement

Insulation resistance measurement assesses the ability of the luminaire or lamp's insulation materials to resist electrical current breakdown. The test applies high voltage and examines whether the insulation is sufficient. This helps detect potential insulation faults that could pose an electrical safety risk.

Grounding Continuity

Grounding continuity measurement checks whether the device's grounding circuit is intact and capable of safely conducting fault current to the ground. The test measures the resistance of the grounding circuit and ensures it does not exceed the limits defined by standards.

Products are also visually inspected to ensure mechanical compatibility of parts. Regular maintenance and inspection of testing and measurement devices are an important part of the laboratory's operations, including annual calibration. This ensures that measurement results remain consistently comparable.